A brief history of ~~time~~ PCBs

A brief history of the PCB, from its inception to its current state.

Printed Circuit Boards, PCBs, form the backbone of modern electronics, housing electrical components and microcontrollers to give devices their functionality. By eliminating the need for long cables and messy wiring, PCBs made it possible for technology to shrink to the compact sizes we rely on today. Almost every piece of technology that you come in contact with today has, as its core, a PCB which controls how the device operates. Yet this was not always the case. Over the decades, PCBs have transformed to keep up with the increasing demand in performance of modern electronics.

PCBs started off as circuits manually wired point-to-point. These circuits were large, messy, and extremely expensive due to the labour-intensive process. At the time, circuits relied on bulky vacuum tubes, since MOSFETs and modern semiconductors had not yet been developed, and so these boards tended to be very large.

Image from audiosciencereview.com user Xulonn

Because circuits were also quite simple during this time, there was no need for PCBs. However, with the miniaturisation of electronics, manual wiring quickly became impractical, creating the need for automation, and thus the PCB.

Paul Eisler, an Austrian engineer, is widely credited with the early invention of the PCB. Recognising the impractical and messy way of implementing circuits, he invented the first PCB around 1936, which was used as part of a radio set in the UK. Eisler’s early prototype involved a thin sheet of metal, where he etched conductive pathways and then covered it with a non-conductive material — the basis of the PCB today. Electrical components could be soldered directly onto the board, making the devices smaller and more reliable, rather than needing to solder electronics directly to the chassis of appliances.

Image from Getty Images

This early PCB concept first saw widespread use in military applications, but it wasn’t until the mid-1950s, after the US Army developed the Auto-Sembly process, which reduced labour requirements, that PCBs entered consumer electronics. Motorola was an early adopter, setting the tone for the rest of the industry. Through-hole construction enabled the rapid manufacture of PCBs by drilling holes into the board and soldering components to copper traces to form connections. This remained standard until surface-mount technology (SMT) gained popularity in the mid-1980s, allowing devices to be soldered directly to the board without drilling. Today, both construction methods are often used together.

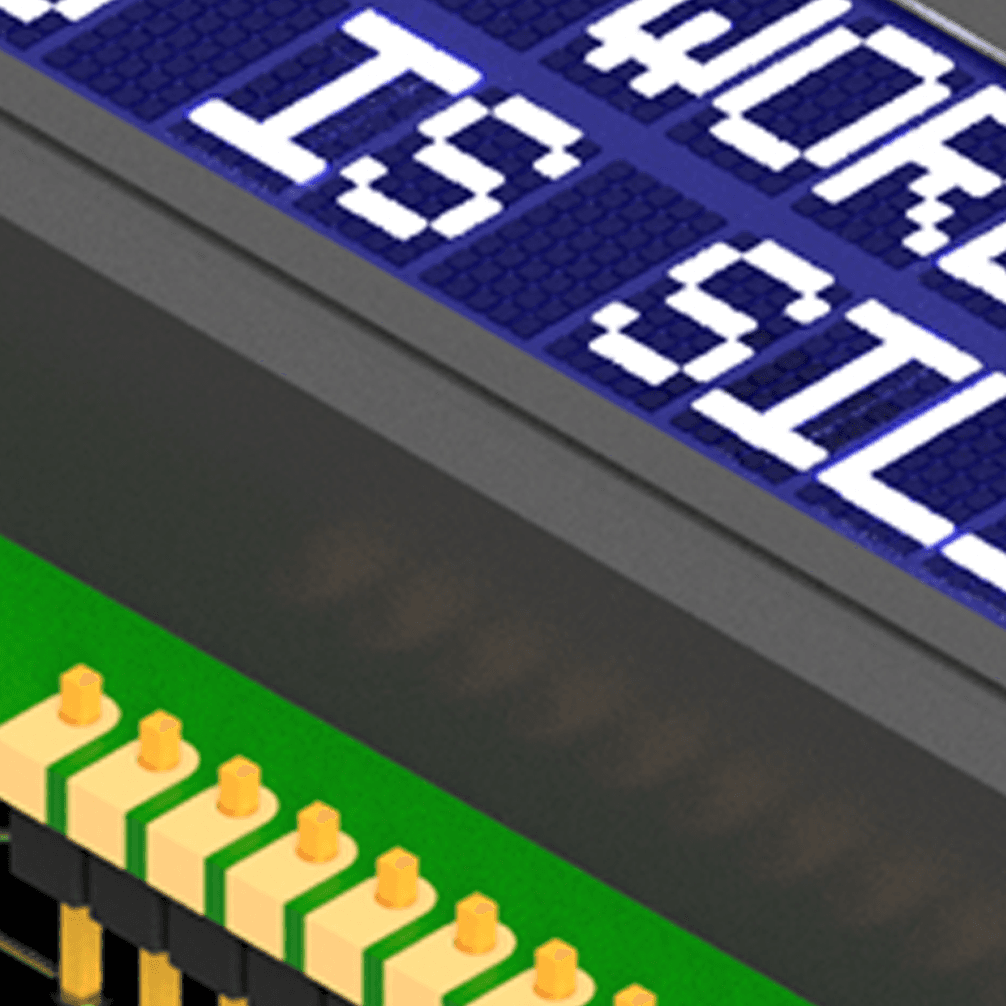

The concept of multilayer PCBs was also introduced in the 1980s to meet the increasing complexity and density requirements of circuits. By stacking multiple layers, engineers could route signals through vias between layers, avoid crossover and interference, and separate ground and power planes to improve electromagnetic compatibility (EMC). Today, most high-tech electronics use multilayer PCBs, optimised for both performance and miniaturisation.

Image from IC-Components.com

Just as CAD revolutionised PCB design in the 1980s, we are now at the start of another shift. Advances in fabrication and chip technology continue to reshape PCB design, but the biggest leap is in how we create them. AI-driven tools are breaking down barriers and accelerating hardware design.

At siliXon, we believe the next step is natural-language integration: where describing your idea in words is enough to generate both the board and its firmware — in minutes, not months.